There are three key indicators that you’re set up to succeed as a custom part buyer —and they all come down to trust.

-

You trust your vendors: their ethics, capabilities, and quality assurances

-

You trust your team: their documentation, industry understanding, and willingness to communicate with you

-

You trust yourself: your relationships, experience, and skillful problem solving

When these indicators are aligned, not only does your job flow smoothly but so do the jobs of everyone in your line of sight, from engineers to operators, estimators to account managers.

However, when you can’t trust your vendors, team, or even yourself, the resulting uncertainty has far-reaching consequences. Distrust can negatively impact your communication, creativity, and ultimately your happiness in your role.

Prior to founding TAKT, I spent 14 years working with contract manufacturing shops where the everyday values exemplified trust. That trust enabled me to drive multimillion-dollar growth and national expansion for those shops in roles that included Operations Manager, Director of Business Development, Sales Engineer, Key Account Executive, and other strategy-focused positions.

I built TAKT to help custom part buyers like you succeed. Get started with TAKT’s five trust-building strategies that you can start using today.

5 Guidelines for Building a Trusted Network for Machined Parts Sourcing

Follow these tips, and you’ll soon have a well-rounded, trustworthy vendor network eager to help you source high-quality parts and thrive as a part buyer.

1. There are no dumb questions (so ask away!)

If you’ve been told only to “get this part made,” it’s time to walk over to the engineer’s desk and ask for a few more details.

-

What kind of equipment is necessary for making this part?

-

What precision machining services do I need to look for?

The answers to these two questions will help you parse your options to select a shop that can make your parts efficiently. Otherwise, you’ll find yourself wasting time engaging with shops that don’t have the capabilities you need.

If you’re unable to get this information from the engineering team for any reason, remember: it’s 100% professionally appropriate for you to ask potential vendors instead. That’s right. You do not have to submit a formal RFQ to ask a machine shop for their input!

It’s your part. Ask questions.

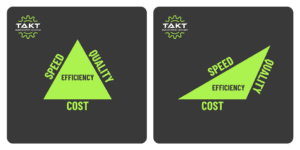

2. Efficiency is the intersection of speed, quality, and cost

As any experienced machinist will tell you, there are multiple ways to manufacture most parts. But not all precision machining methods are created equal.

Some machines offer a “one and done” solution. Examples include 5-axis machines, live tool lathes, Swiss machines, and multitasking machines, any of which can complete a part using a single, start-to-finish process.

Think of efficiency as a triangle. Each side of the triangle represents a facet of efficiency. On one side, there’s speed—typically the first trait that comes to mind. On the other sides, you’ll find quality and cost.

As a rule, an efficient operation looks like an equilateral triangle, with speed, quality, and cost equally represented. However, for various reasons, you may occasionally need to prioritize one consideration over the others, making for a less equal triangle.

Framed differently: the fastest manufacturing method may exceed your budget. Or the most affordable process may not deliver the quality you require. And you may find that the best quality simply takes too long.

As you navigate all of your options, don’t hesitate to ask, “What is the most efficient way to get this part made?” A shop that helps you balance speed, cost, and quality is a shop you want to work with!

TAKT Tip: Choose a one-stop shop

TAKT Manufacturing Solutions helps buyers like you with their machined parts sourcing. We’ll become familiar with your requirements, help you understand the possibilities, and outline your options so you can make an informed decision. All it takes is one no-obligation call or email to get the process started!

3. Materials are like people—they’re all unique

You already know that not all precision machining services are equal. The same is true for materials, too. While the average consumer thinks in broad terms like “metal” or “plastic,” manufacturers know that each material has dramatically different properties rendering it right (or wrong) for a part.

Your engineering team has likely already identified the material they want or need. Now it becomes your job to find vendors who understand that material and know how to machine it.

Titanium, for example, has the highest strength-to-density ratio of any elemental metal. Its high melting point, elasticity, and biocompatibility make it a popular choice for medical, aerospace, marine, and defense applications. But not every shop is willing to work with titanium. The same properties that make titanium desirable also make it expensive and difficult to machine.

Materials that are very hard, very soft, or have unusual properties are the most likely to be turned down by a machine shop. When you’re familiar with a part’s material, you can pinpoint shops with extensive experience machining that material.

TAKT Tip: Don’t confuse excitement with expertise

At TAKT, if we aren’t equipped to deliver a product we’ll be proud of, we don’t take the job. Period. Some shops aren’t as discerning, though, and they’ll happily accept any job—even if they don’t have adequate experience with the material or method.

The key for buyers is never to assume that a shop’s excitement = expertise. Someone at the machine shop should be able to explain precisely how they’ll fulfill your project. If a shop can’t intelligently discuss their approach to your part, you’re probably better off going elsewhere for your machined parts sourcing.

4. Sometimes you need a certified shop, and sometimes compliant is good enough

Certifications like ISO 9001:2015 and AS9100 are a big deal—and come with a hefty price tag. A single certification costs a shop around $25,000!

The good news is that many parts don’t need to be made by a certified vendor; compliance is often enough.

Certified shops

A certified shop has paid an auditor to verify their adherence to specific quality management system (QMS) requirements, from generalized ISO requirements to aerospace-specific AS9100 requirements.

Due to the high cost of certification, a certified shop’s hourly rates are commonly more expensive. Granted, an AS9100-certified shop’s parts can go directly into space! But if you don’t need that benefit, why pay more?

Compliant shops

Some shops forgo costly certifications but utilize a QMS based upon ISO 9001:2015 requirements. After all, why should a shop pursue certifications if the parts they make don’t require them? (Prototypes are prime examples of these parts.)

If certification isn’t necessary, you’ll find that you can save time and money by choosing a compliant shop instead of a certified shop for machined parts sourcing.

5. Budget transparency is helpful, not hurtful

As a custom part buyer, you may worry that revealing your team’s budget will “tip your hand” and invite quotes that bump up against your budget ceiling. With most modern machine shops using a streamlined quoting workflow, price tampering is highly unlikely. And if you’re still uncertain, TAKT can help you identify trusted resources. Our team is on-hand to help seven days a week!

To begin, you’ll want to notate your ideal budget in your RFQ—this can be your total budget or your per-part price range.

With this information in hand, shops can respond with a no-quote if they’re unable to meet your budgetary needs, saving everyone time. Some shops will suggest budget-friendly trade-off solutions, such as offering on-budget 5-axis machining if you can extend your turnaround time.

You may be surprised to learn that budget-related conversations form powerful in-roads with vendors. Everyone appreciates honesty and sincerity, and conversations about money are about as candid as you can get! These dialogues form foundations for healthy vendor relationships—now and in the future.

TAKT Tip: You’re in the driver’s seat

As the buyer, YOU are in the driver’s seat. You decide which direction to take, how fast you’ll drive, who gets to ride with you—and of course, you pick the music!

So before you go shopping for your next vendor, remember:

-

Ask lots of questions

-

Balance your efficiencies: speed, quality, and cost

-

Know your material’s properties

-

Determine the need for certified vs. compliant

-

Embrace budget transparency

Because when you know what you want and communicate it clearly, you can’t help but win!